Anyone who wants to work cost-efficiently and profit-oriented in mining today automates the work processes involved. The technology used for this purpose must meet the highest requirements: absolute precision and reliability, seamless monitoring of all relevant measurement and process variables, flexible machine control in order to be able to react to changing mining-specific conditions - all in the service of maximum safety

So that everything remains connected

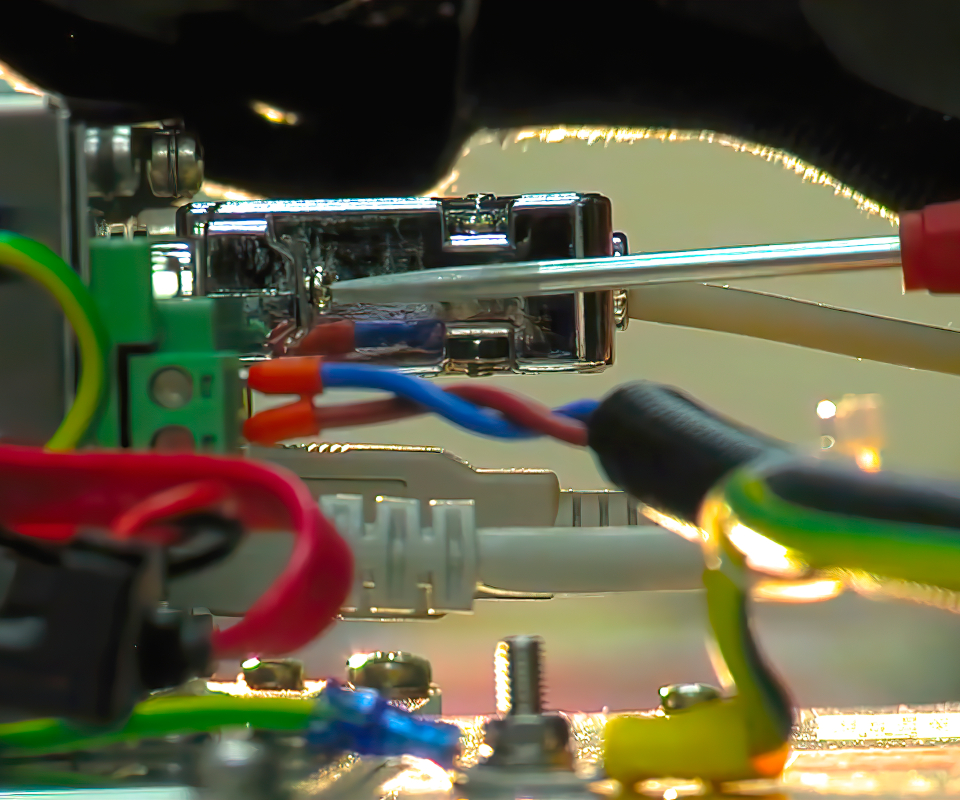

For the automated coal production electronic components such as electro-hydraulic controls, power supplies, emergency stop switches, PLC modules, industrial PCs, pressure and displacement sensors and all connecting cables are required.

All steps for the production of the individual devices are carried out by EEP itself. This ranges from the design and layout of a circuit board for the electronic controls to the construction, assembly and function test of complete devices.

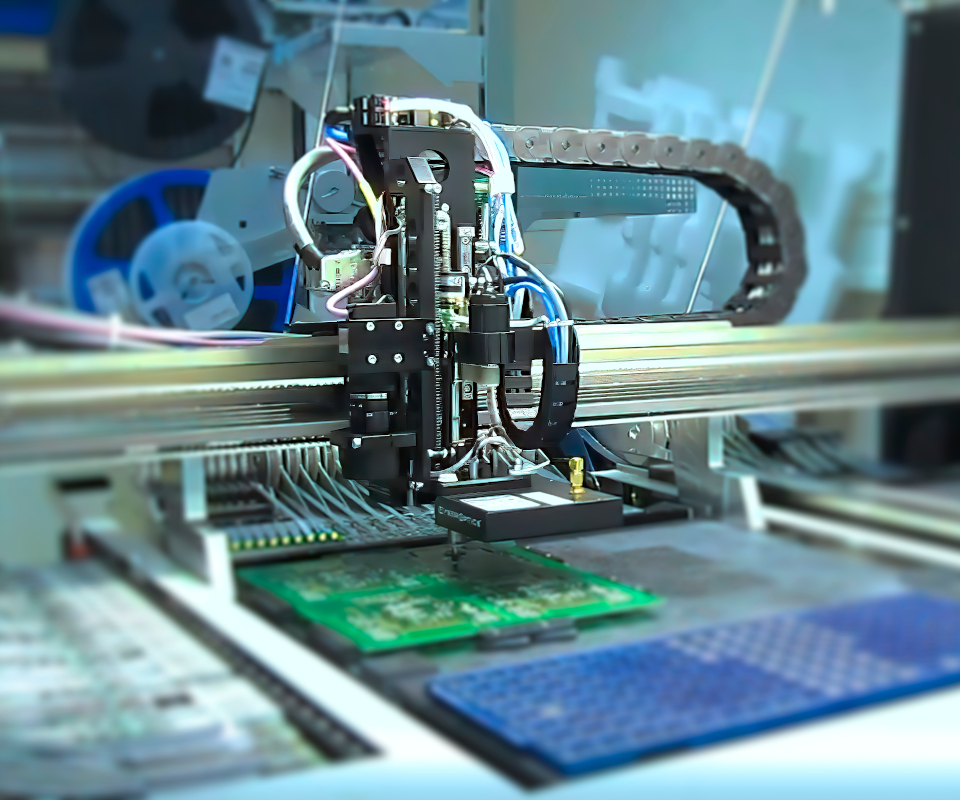

Electronic circuits can be developed, tested and the corresponding layout can be created at several workstations. The assembly of the boards with electronic components is done by automatic assembly machines.

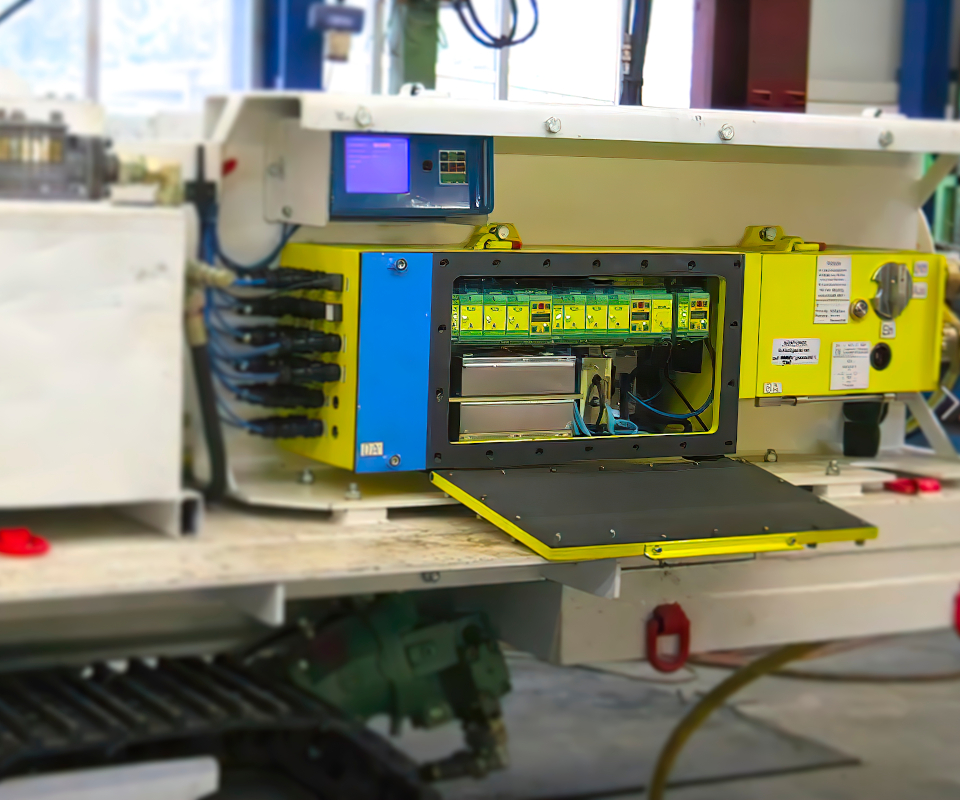

Parallel to the production of the circuit boards, the mechanical assembly and the assembly of housings, plugs or switches takes place. After the installation of all electronic components, each device is subjected to an intensive function test. Automated test benches for each type of device simulate the real operation and check each individual function for possible errors. After passing the test period with protocol, the devices are packed ready for shipment.

PRA_matic®

The "heart" in the series of intelligent and innovative EEP products and applications is PRA_matic® - a complete longwall control system for underground coal mining. The intrinsically safe PRA_matic® control units developed by EEP ensure absolutely precise electro-hydraulic control of the longwall shields and can perform up to 24 functions automatically.

EEP also offers powerful programmable logic controllers (PLC) and the necessary couplers for the control and monitoring of all other required components and systems.

In addition to use in underground mining, the intrinsically safe components are also suitable for the automation of processes in other explosion-hazardous areas, such as in the chemical industry.